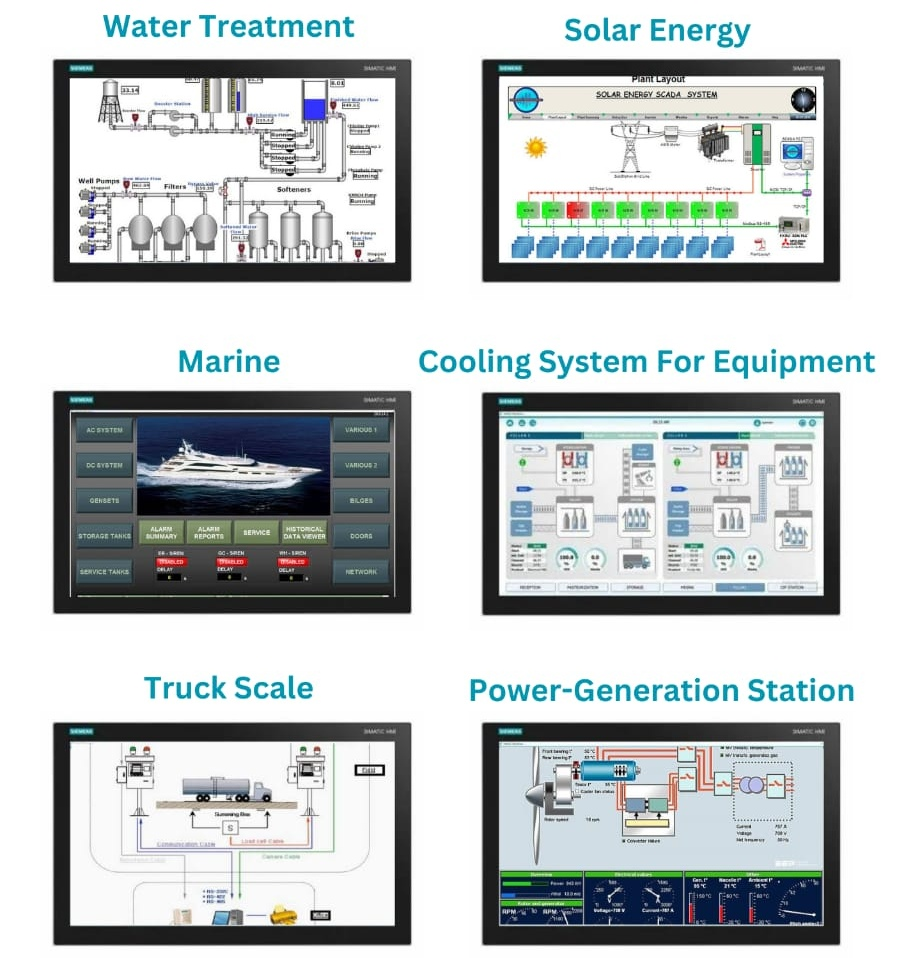

SCADA, which stands for Supervisory Control and Data Acquisition, is a powerful industrial control system that plays a critical role in various sectors like power plants, water treatment facilities, oil and gas pipelines, and manufacturing plants. It acts as the central nervous system, monitoring and controlling complex processes in real-time, ensuring smooth and efficient operation.

Power Plants:

Real-time monitoring of critical parameters: SCADA continuously tracks temperature, pressure, and other vital data in boilers, turbines, and generators, ensuring safe and efficient operation.

Remote control of equipment: Operators can remotely adjust settings, start and stop generators, and optimize power output based on demand.

Early detection of faults: SCADA systems trigger alarms for abnormal readings, enabling operators to take corrective action and prevent potential accidents

Water Treatment Plants:

Automated control of water flow and treatment processes: SCADA ensures precise dosing of chemicals, filtration, and disinfection, guaranteeing clean and safe drinking water.

Leak detection and pressure monitoring: The system promptly identifies and locates leaks, minimizing water loss and damage.

Optimization of resource consumption: SCADA helps optimize chemical usage and energy consumption for efficient water treatment.

Plant Operations:

Real-time production monitoring: SCADA tracks production variables like flow rates, product quality, and machine performance, enabling optimization and continuous improvement.

Predictive maintenance: By analyzing historical data, SCADA helps predict equipment failures and schedule preventive maintenance, reducing downtime and costs.

Improved safety: The system monitors safety parameters like temperature, pressure, and emissions, preventing accidents and environmental hazards

Benefits of SCADA Systems:

Increased efficiency and productivity: Real-time data and control capabilities lead to optimized processes and higher output.

Reduced costs: SCADA minimizes waste, downtime, and energy consumption, leading to cost savings.

Improved safety and reliability: Continuous monitoring and automated controls enhance safety and prevent equipment failures.

Better decision-making: Data-driven insights enable informed decisions for efficient plant operation and resource allocation